Tuesday, April 8, 2025

Supplier compliance in the food and beverage industry is no longer just a regulatory requirement—it’s a critical factor in maintaining quality, safety, and brand integrity.

Maikel Fontein

Apr 8, 2025

10

min

Supplier compliance in the food and beverage industry isn’t just a box to check—it’s a critical line of defense against recalls, audit failures, and reputational damage. Yet for many teams, managing supplier questionnaires and documentation is still a manual, chaotic process. Think endless email threads, outdated spreadsheets, and last-minute scrambles before audits.

In this blog, we’ll explore why manual methods no longer cut it—and how automation is transforming supplier compliance into a scalable, intelligent system. From centralized portals to real-time risk scoring, discover how leading F&B companies are using automation to streamline approvals, respond faster to regulatory changes, and build more resilient, responsible supply chains.

Why Are Manual Supplier Compliance Methods No Longer Sustainable?

Tracking supplier documentation through email and spreadsheets might work for a handful of vendors—but not for fifty, five hundred, or even more. Manual workflows introduce several critical challenges:

Inconsistent Checks Across Teams or Sites: When different departments or locations follow varying processes, compliance becomes fragmented. For instance, a small local bakery might use a simple email system to manage certifications, while a large beverage distributor might rely on outdated spreadsheets. The result is a patchwork of inconsistent data, making it difficult to uphold uniform quality and safety standards.

Lack of Real-Time Visibility: In a manual system, updates from suppliers often come in sporadically. Consider a dairy supplier that submits updated health and safety certifications via email. Without a centralized system, procurement or quality teams might not receive or process the latest version promptly, leaving the business exposed to potential compliance lapses.

Last-Minute Surprises During Audits: Imagine preparing for a critical audit only to discover that several suppliers—perhaps a handful of spice providers or ingredient growers—have expired certifications or missing documents that were never flagged. These surprises not only delay the audit process but can also lead to penalties or a temporary halt in operations.

Slow Response Times to Retailer or Regulator Questionnaires: When retailers or regulatory bodies request proof of compliance, manual processes often result in time-consuming data hunts. For example, a major retailer might require updated allergen information and sustainability practices from a range of suppliers. Relying on scattered emails and spreadsheets means slower responses, potentially jeopardizing key business relationships.

This reactive, manual approach not only increases risk but also drains team bandwidth. Instead of proactively managing compliance, teams are forced into crisis mode—scrambling to collect, verify, and update documentation.

How Does Automation Solve the Supplier Compliance Bottleneck?

Automation transforms supplier compliance from a manual, error-prone challenge into a streamlined, efficient process. Here’s how digital automation tools make a significant difference:

Seamless Data Integration: Automation platforms connect with your ERP, ESG systems, QMS, and shared drives, consolidating all supplier documentation into one centralized hub. This ensures that certifications—whether food safety certificates from spice vendors or organic credentials from local farms—are easily accessible and always up-to-date.

Intelligent Questionnaire Management: Automated systems distribute customized compliance questionnaires to all suppliers simultaneously and collect responses efficiently. They learn from previous submissions to minimize redundancy and ensure that each supplier receives the right set of questions tailored to their profile and risk level.

Proactive, Real-Time Alerts: Automation continuously monitors supplier data and sends immediate alerts when documents are missing or nearing expiration. This proactive approach means that overdue allergen updates or expiring certifications are flagged well before they become a compliance issue, reducing the risk of audit surprises.

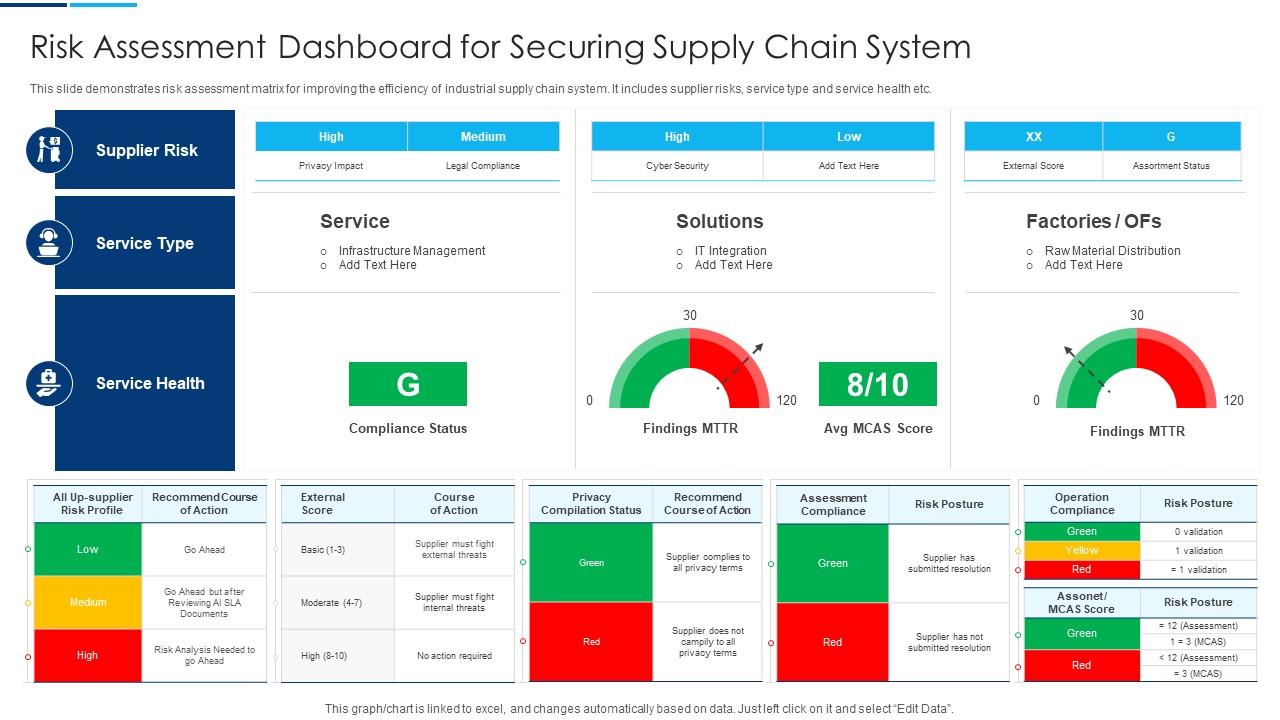

Integrated Risk Management: By linking compliance responses directly to dynamic risk profiles, automation tools help prioritize suppliers based on their risk level. If a supplier repeatedly delays responses or provides incomplete documentation, their risk score adjusts automatically, enabling your team to focus on high-risk vendors and make informed decisions swiftly.

Multi-Format Support and Audit Readiness: Automated solutions standardize diverse document formats—be it PDFs, Excel files, or online forms—into a cohesive system. When auditors or retail partners request proof of compliance, comprehensive and up-to-date reports can be generated within minutes, not days.

What Is a Central Supplier Portal—and Why Do You Need One?

A central supplier portal is a dedicated, digital hub that brings all your supplier compliance data together in one accessible place. It enables your vendors to manage their own compliance documents and updates, while your internal teams can quickly access the information they need. Key features include:

Document Upload: Suppliers can effortlessly upload certifications such as GFSI, Organic, and Halal, ensuring that all required credentials are stored in one secure location.

Digital Questionnaire Completion: Vendors complete tailored digital questionnaires—covering areas like EUDR, ESG, and allergen declarations—streamlining data collection and reducing manual entry errors.

Corrective Action Response: The portal facilitates direct responses to corrective action requests, ensuring that issues are resolved quickly and tracked efficiently.

Real-Time Compliance Tracking: With instant updates, you can monitor supplier compliance statuses in real time, eliminating the need for time-consuming follow-ups.

By centralizing these functions, a supplier portal ensures uniform data, speeds up onboarding, and removes the need to sift through countless emails and documents. It creates a transparent, efficient process that benefits both suppliers and internal teams, fostering a more agile and compliant supply chain.

How Can Automated Questionnaires Keep You Ahead of Regulatory Change?

Automated questionnaires empower your organization to adapt swiftly to new regulatory requirements without overburdening your team or suppliers.

Rapid Integration of New Regulations: When a new regulation is introduced, such as updated food safety standards or sustainability mandates, you can quickly add additional questions to your digital supplier forms. For example, if a new labeling law is enacted, your system can prompt suppliers to provide updated certification details without delay.

Targeted Updates for Specific Requirements: Suppose regulators require proof of compliance with EUDR standards. Automated questionnaires allow you to instantly roll out targeted updates to the relevant sections of your forms, ensuring that every supplier provides the necessary evidence without waiting for manual intervention.

Scalable Collection of ESG Data: As sustainability becomes a critical focus, digital questionnaires make it simple to collect comprehensive ESG declarations from your entire supplier network. Whether you're assessing carbon footprints or verifying fair labor practices, automation streamlines data capture across all vendors, large or small.

Every response is stored in a searchable, auditable repository—ensuring that your compliance records are not only up-to-date but also easily accessible for internal reporting and external audits.

How Do Automated Workflows Improve Supplier Approval Processes?

Here’s how automated workflows transform supplier onboarding and approvals:

Quality teams verify test results and certifications: For example, when onboarding a poultry supplier, quality teams are automatically prompted to review HACCP plans, microbiological test results, or third-party food safety certifications like BRC or IFS. Once uploaded into the portal, these documents are flagged for validation before the supplier moves forward.

ESG teams assess sustainability claims: If a supplier of cocoa or coffee claims to be deforestation-free or fair-trade certified, automation routes their ESG documentation—such as carbon emissions data, traceability declarations, or human rights policies—directly to the sustainability team for review.

Procurement confirms certifications and commercial terms: Procurement teams can verify supply contracts, check expiry dates on documents like Organic or Halal certifications, and ensure pricing and delivery terms are in place. If any documents are missing or outdated, the system automatically flags the issue and notifies the supplier.

Finance reviews payment terms and risk exposure: Finance teams are looped in to review payment agreements, currency risks, or tax documentation—ensuring that all financial details are finalized before orders are placed.

Once all teams complete their checks, the system automatically marks the supplier as “approved.” If even one step is incomplete—say, a missing pesticide test report or an outdated Sedex audit—the supplier remains on hold until the issue is resolved. Automated reminders are sent to both suppliers and internal teams, keeping the process moving without manual chasing.

What Role Does Risk Scoring Play in Supplier Oversight?

Here’s how it works in practice:

Country of Origin: A vanilla supplier from a high-risk country for labor violations or deforestation may be flagged for enhanced due diligence, while a local dairy supplier operating in a highly regulated region may receive a lower risk score.

Ingredient Category: High-risk ingredients like shellfish, peanuts, or spices (which are prone to contamination or fraud) are automatically scored higher. This prompts more frequent audits or additional documentation requirements compared to low-risk items like sugar or salt.

Historical Compliance Behavior: If a packaging supplier has a history of late document submissions, non-conformances, or audit failures, the system increases their risk score—triggering more frequent checks or escalation to management. Meanwhile, long-term partners with clean records may qualify for lighter oversight.

Certification Levels and Expiry: Suppliers with expired or lower-tier certifications (e.g., lacking GFSI recognition or with pending corrective actions) are considered higher risk. Automation monitors expiry dates and flags issues proactively—no more relying on someone to manually check a spreadsheet.

Once assigned, these scores directly influence the level of scrutiny a supplier receives:

High-risk suppliers may need to complete detailed ESG or safety questionnaires, undergo quarterly audits, or submit third-party test results more frequently.

Low-risk suppliers are placed on a lighter track, freeing up internal resources to focus where it counts.

Automated risk scoring ensures consistency, transparency, and focus—so your team isn’t micromanaging low-risk vendors or overlooking potential trouble spots. Instead, you’re working smarter, not harder—focusing on prevention, not reaction.

How Does Automation Support Ethical and Sustainable Supply Chains?

Here’s how questionnaire automation elevates your sustainability efforts:

Comprehensive ESG Data Capture:

Automation platforms systematically collect detailed information from suppliers on crucial ESG issues such as fair labor practices, greenhouse gas emissions, deforestation policies, animal welfare standards, and water stewardship. For example, a cocoa supplier can seamlessly report deforestation-free sourcing commitments, while a seafood vendor provides transparent data on sustainable fishing certifications—without the burden of repetitive paperwork.

Transparent, Auditable Reporting:

Automated systems centralize ESG documentation, enabling real-time reporting for investors, certifiers, regulators, and customers. If an investor requests your emissions footprint or a retailer requires proof of compliance with new deforestation regulations (like the EUDR), you can quickly generate clear, credible reports directly from the supplier data portal.

Proactive ESG Risk Identification:

Instead of reacting to ethical or sustainability issues after they've surfaced publicly, automated workflows flag potential ESG risks proactively. For instance, if a supplier consistently delays submitting fair-trade certification or reports non-compliant labor conditions, the platform immediately alerts your ESG and procurement teams. This allows timely intervention, preventing reputational damage and regulatory penalties.

Supplier Engagement and Continuous Improvement:

Automation provides suppliers clear visibility into expectations and status, encouraging proactive participation in ESG initiatives. Regular automated communications, renewal reminders, and corrective action workflows engage suppliers in ongoing improvement. For example, a packaging supplier identified as using non-recyclable materials receives targeted feedback and improvement guidelines directly through the automated system—driving continuous progress toward sustainability targets.

Can Automation Make Audit Prep and Retail Requests Easier?

Absolutely. Automation transforms what was once a frantic scramble for documents into a streamlined, on-demand process. Here's how:

Instantly Generate Supplier Lists:

Imagine needing to prove compliance to a major retailer—automation lets you generate an up-to-date list of suppliers with valid certifications in seconds. No more sifting through emails or outdated spreadsheets.

Seamless Data Retrieval:

Automated systems pull ESG, traceability, and quality data directly from recent questionnaire responses and centralized databases. For instance, if an auditor requests detailed traceability data for a particular ingredient, you can quickly compile and present accurate, real-time information.

Regulatory Compliance Proof:

Showcase compliance with specific regulations—be it Germany's Lieferkettengesetz or the EU Deforestation Regulation—without the hassle of manual document searches. The system automatically tags and stores documentation, so relevant proofs are always just a few clicks away.

This level of automation not only saves time but also builds credibility with partners, regulators, and customers by ensuring that compliance data is both reliable and readily accessible when it matters most.

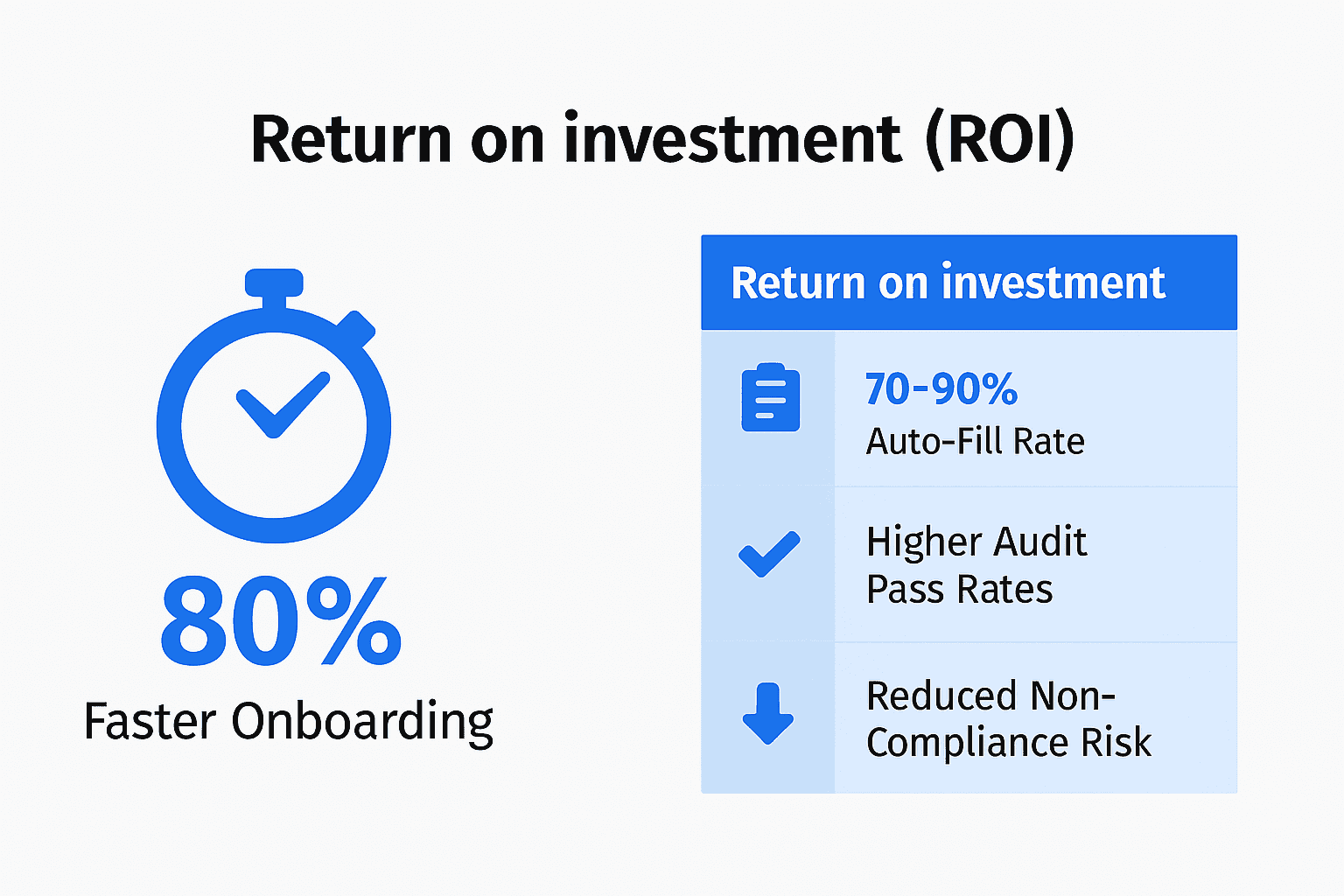

What’s the ROI of Automating Supplier Questionnaires?

Companies adopting supplier compliance automation consistently report significant and measurable benefits, demonstrating clear returns on their investment. Here's how automation delivers value in practical terms:

80% Time Savings During Onboarding:

Supplier onboarding—previously involving weeks of emails, follow-ups, and manual document handling—can now be completed in days or even hours. Imagine your procurement team onboarding a new organic spice supplier; instead of weeks of chasing certification documents, automation streamlines collection, verification, and approval seamlessly.

70–90% Questionnaire Auto-Fill Rate:

Automation significantly reduces the manual workload by intelligently retrieving and pre-populating repetitive responses. When completing annual ESG or food safety surveys for major retailers like Tesco or Carrefour, your team no longer spends hours copying data from previous submissions. Instead, they review auto-filled responses and make targeted adjustments as needed.

Higher Audit Pass Rates:

With compliance documentation consistently organized, accessible, and up-to-date, audit preparedness improves dramatically. Companies frequently report fewer surprises during external audits, reduced preparation time, and significantly higher first-time pass rates for audits by bodies like BRC, Sedex, or EcoVadis.

Faster Response to Retailer and Customer Demands:

Automation enables rapid, accurate responses to urgent retailer requests. For instance, if a retailer demands immediate verification of allergen management or compliance with the EU Deforestation Regulation (EUDR), your compliance team can swiftly pull validated responses from a centralized, automated platform—ensuring both responsiveness and accuracy.

Reduced Risk of Non-Compliance and Recalls:

Proactive management of supplier certifications and compliance status minimizes critical risks such as recalls, penalties, or reputational harm. For example, automated alerts and reminders for expiring certifications, outdated documentation, or compliance gaps help companies avoid costly disruptions and brand damage.

In short, automating supplier questionnaires delivers substantial efficiency gains, risk reduction, and strategic agility. It enables teams to shift their focus from manual, repetitive tasks to meaningful initiatives that improve overall business resilience, sustainability, and reputation.